1. SSCD350-1250/4500 350 kW Nieuwe energiemotor Elektrische dynamometer

Het SSCD350-1250/4500 350kW Motor Performance Dynamometer Bench System is een uitgebreid testplatform met een hoge prestatie dat speciaal is ontworpen voor het testen van motoren met een midden- en groot vermogen.Dit systeem bevat kernmodules zoals een dynamo, een hoge-precisie koppel sensor, een intelligent meet- en besturingssysteem en een langeafstandsbatterijsimulator,een uitgebreide dekking van de prestatieverificatiebehoeften van aandrijvingsmotoren voor bedrijfsvoertuigen, industriële middelgrote en grote motoren en speciale motoren.

| Naam van het onderdeel |

Kernspecificaties |

Brandnaam |

| Elektrische dynamo SSCD350-1250/4500 |

Vermogen: 350 kW; nominale snelheid: 1250 t/min, nominale koppel: 2674 Nm, maximale snelheid: 4500 t/min, constante vermogen: 1250-3750 t/min, watergekoeld; |

Seelong |

| Torkflens |

Torcelflanse: 0-3000Nm (nauwkeurigheid: 0,2%FS) |

HBM |

| Variabele frequentie-omvormer |

Inlaatspanning: driefasige wisselstroom 380V±10%; Frequentie: 50-60Hz; Overstromingsbeschermingswaarde: 1,5 maal nominale stroom; Meerdere beschermingssystemen tegen overbelasting, overspanning en oververhitting. |

ABB |

| XLP-1000 meet- en regelingssysteem |

Industriële pc's: IPC710, CPU: i7, geheugen: 32 GB, harde schijf: 1 TB, XLP-1000 Mees- en besturingssysteemsoftware |

Seelong |

| Systemen voor het verkrijgen van gegevens |

Het omvat een trillingsopname-eenheid, een temperatuuropname-eenheid, een analoge inputopname-eenheid en een digitale inputopname-eenheid. |

Advantech ADAM-4017+ |

| Vermogensanalysator |

Model: WT5006

Basisnauwkeurigheid: 0,03% (0,01% van de waarde + 0,02% van het bereik)

Bandbreedte: DC, 0,1 Hz - 1 MHz

LCD touchscreen

6-kanaal + MTR

|

Seelong |

| Stroomtransformer |

1000A, 0,05% FS |

|

| Batterijsimulator |

Uitgangsspanning: 24-1200V

Nominaal vermogen: 300 kW

Piekvermogen: 375 kW

Nominale stroom: 800A

Piekstroom: 1000 A

terugslagspanning: 323-427V

Simulatie van batterijen: het kan zeven soorten batterijen simuleren: drievoudige lithiumbatterijen, lithiummanganesoxidebatterijen, lithiumtitanaatbatterijen, lithiumcobaltoxidebatterijen,met een vermogen van niet meer dan 10 W, loodzuurbatterijen en nikkel-metaalhydridebatterijen.

|

Seelong |

| Facultatief |

| Koppeling |

Toegestane snelheid: 5000 t/min, toegestane koppel: 3000 Nm |

Seelong |

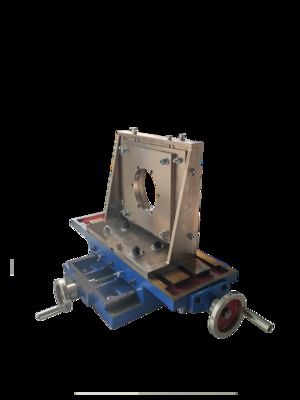

| Motorbeugel |

Beugelstelbereik (hoogte van het motorcentrum): 200 mm-500 mm |

Seelong |

| Platen van gietijzer |

Materiaal: HT300 (trekkracht ≥ 300 MPa); schokdempers en gietijzeren platen zorgen voor stabiliteit tijdens tests met hoge snelheid. |

Seelong |

| Schokdempers |

De springschokdempers en gietijzeren platen zorgen voor stabiliteit bij tests met hoge snelheid. |

Seelong |

2. SSCD350-1250/4500 350 kW elektrische dynamometer Technische parameters

| Parameterklassen |

Technische indicatoren |

| Fabrikant van dynamometers |

Seelong |

| Nominaal vermogen |

350 kW. |

| Nominaal koppel |

2674Nm |

| Nominale snelheid |

1250 rpm |

| Maximale snelheid |

4500 t/min |

| Variabiliteitsbereik met constant koppel |

0-1250 rpm |

| Constante vermogen en toerental |

1250-3750 t/min. |

| Model van de koppelsensor |

T40B |

| Vervaardiger van koppelsensoren |

HBM |

| Torcensensorbereik (Nm) |

0-3000Nm |

| Genauigheidsniveau |

00,2% FS |

3. SSCD350-1250/4500 350kW Motorprestaties Elektrisch dynamometerbank systeem Kernvoordelen

1) Alomvattende prestatie dekking: De kerndynamometer heeft een vermogen van 350 kW, een koppelbereik van 0-3000 Nm en een maximale toerental van 4500 t/min.Het constante vermogen van 1250-3750 rpm is geschikt voor verschillende motorfunctiekarakteristieken.

2) Uitstekende meetnauwkeurigheid: De HBM-koppelflens heeft een nauwkeurigheid van 0,2% FS en de Seelong-vermogensanalysator heeft een basiswaarheid van 0,03%.het zorgt voor nauwkeurige verzameling van belangrijke gegevens zoals koppel, vermogen en temperatuur.

3) Sterke systeemcompatibiliteit: De batterijsimulator ondersteunt 7 standaardbatterijmodellen met een uitgangsspanning van 24-1200 V en een piekstroom van 1000 A, die zich aanpassen aan de voedingsbehoeften van verschillende typen motoren;het ABB-frequentiekonverteringssysteem is compatibel met een brede ingangsspanning van 380V±10% en heeft een uitstekende stabiliteit.

4) Volledige en flexibele configuratie: Het omvat kernmodules zoals meting en besturing, gegevensopname en vermogensanalyse.De beugel heeft een instelbereik van 200 mm-500 mm om zich aan te passen aan verschillende installatievereistenDe combinatie van gietijzeren plaat en springschokdemper zorgt voor teststabiliteit.

4. SSCD350-1250/4500 350kW motorprestaties Elektrische dynamometer bench systeem toepassingsgebieden

1) Nieuwe energievoertuigen: Geschikt voor de prestatieonderzoek van aandrijvingsmotoren (inclusief personenauto's en bedrijfsvoertuigen) voor nieuwe-energievoertuigen, met inbegrip van vermogen, koppel, efficiëntie en duurzaamheid,om te voldoen aan de aanpassingsbehoeften van de reguliere batterijen, zoals ternarisch lithium en lithium-ijzerfosfaat.

2) Industrieel motorveld: Wij kunnen fabrieks- en type-tests uitvoeren op industriële asynchrone motoren en synchrone motoren van 350 kW en lager,betreffende de prestatieverificatie van ondersteunende motoren zoals waterpompen, ventilatoren en compressoren.

3) Speciaal motorisch veld: Geschikt voor gespecialiseerde tests van speciale motoren met een middellange en hoge vermogensvermogen die worden gebruikt in machines, schepen, spoorvervoer en andere situaties,voldoet aan de testvereisten voor een hoog koppel en een breed toerentalbereik.

4) O&O- en testinstellingen: Het leveren van R & D-platformen voor motorprestaties en het testen van de naleving van standaarden voor universiteiten, onderzoeksinstituten en derde-partij-testinstellingen;en ondersteuning van de implementatie van op maat gemaakte testoplossingen.

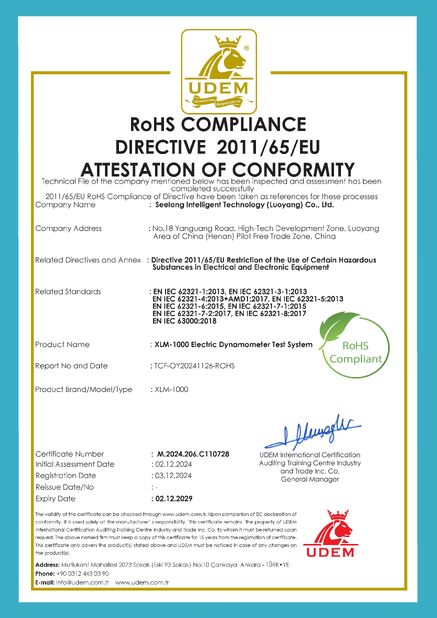

5. SSCD350-1250 /4500 350kW motorprestaties Elektrische dynamometer bench systeem referentienormen

1) Nationale normen:

GB/T 18488.1-20 24 "Aandrijmotorsystemen voor elektrische voertuigen - Deel 1: Technische voorwaarden",

GB/T 18488.2-20 24 "Aandrijmotorsystemen voor elektrische voertuigen - Deel 2: Testmethoden",

¥GB 755-2019 "Klassificaties en prestaties van roterende elektrische machines",

JB/T 10634-20 23 "Elektrische dynamometer".

2) Internationale normen:

¢ISO 15084-1:2017 Wegvoertuigen - Elektrische aandrijfsystemen - Deel 1: Stroominterfaces;

IEC 60034-1:2017 Roterende elektrische machines - Deel 1: Kwalificaties en prestaties.

3) Industrieel gerelateerd: Componenten zoals batterijsimulatoren en vermogensanalysatoren voldoen aan de desbetreffende industriële nauwkeurigheids- en veiligheidsnormen (bijv. de koppelsensor HBM T40B voldoet aan ISO 16613:Kalibratiestandaard 2013, en het ABB-frequentieomrekeningssysteem voldoet aan de IEC 61800-5-1 veiligheidsnorm).

6. Modellijst van het motorprestatiedynamometertestbank systeem

| Model |

Vermogen (kW) |

Tork (Nm) |

Nominale snelheid (rpm) |

Maximale snelheid (rpm) |

Naast de in punt 6.2.4.1 bedoelde parameters moet de in punt 6.2.4.2 bedoelde parameters worden gebruikt. |

| SSCD15-1000/4500 |

15 |

143 |

1000 |

4000 |

00,2% FS |

| SSCD30-1000/4500 |

30 |

286 |

1000 |

4000 |

00,2% FS |

| SSCD45-1000/4000 |

45 |

430 |

1000 |

4000 |

00,2% FS |

| SSCD60-1000/4000 |

60 |

573 |

1000 |

4000 |

00,2% FS |

| SSCD75-1000/4000 |

75 |

716 |

1000 |

4000 |

00,2% FS |

| SSCD90-1000/3500 |

90 |

859 |

1000 |

3500 |

00,2% FS |

| SSCD110-1000/3500 |

110 |

1050 |

1000 |

3500 |

00,2% FS |

| SSCD160-1000/3500 |

160 |

1528 |

1000 |

3500 |

00,2% FS |

| SSCD200-1000/3300 |

200 |

1910 |

1000 |

3300 |

00,2% FS |

| SSCD250-1000/3300 |

250 |

2387 |

1000 |

3300 |

00,2% FS |

| SSCD300-1000/3300 |

300 |

2865 |

1000 |

3300 |

00,2% FS |

| SSCD30-1500/5000 |

30 |

191 |

1500 |

5000 |

00,2% FS |

| SSCD45-1500/5000 |

45 |

286 |

1500 |

5000 |

00,2% FS |

| SSCD60-1500/5000 |

60 |

382 |

1500 |

5000 |

00,2% FS |

| SSCD90-1500/5000 |

90 |

573 |

1500 |

5000 |

00,2% FS |

| SSCD132-1500/4500 |

132 |

840 |

1500 |

4500 |

00,2% FS |

| SSCD160-1500/4500 |

160 |

1019 |

1500 |

4500 |

00,2% FS |

| SSCD200-1500/4000 |

200 |

1273 |

1500 |

4000 |

00,2% FS |

| SSCD250-1500/4000 |

250 |

1592 |

1500 |

4000 |

00,2% FS |

| SSCD300-1500/3800 |

300 |

1910 |

1500 |

3800 |

00,2% FS |

| SSCD350-1250/4500 |

350 |

2674 |

1250 |

4500 |

00,2% FS |

| SSCD400-1500/3800 |

400 |

2546 |

1500 |

3800 |

00,2% FS |

| SSCD500-1500/3800 |

500 |

3183 |

1500 |

3800 |

00,2% FS |

| Vermogen, snelheidsbereika.Het aantal aankoopmodules kan worden aangepasta.s Vereist. |

7Leverings- en naverkoopservice

Levering:Standaardmodellen worden binnen 90 dagen verscheept; op maat gemaakte modellen binnen 90-180 dagen (inclusief internationale logistieke en douaneafhandelingshulp).

Naverkoopservice:1 jaar garantie op kerncomponenten (dynamometer, koppelflanse), levenslange tweetalige (Chinees en Engels) technische ondersteuning (responstijd ≤ 4 uur);de reserveonderdelen binnen 24 uur binnen het land worden verzonden en binnen 7 dagen internationaal worden geleverd;; 1,5 dagen gratis operatietraining verstrekt; ondersteuning van remote debugging (computergebaseerde, inclusief modulaire oplossingconfiguratie begeleiding).

Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!  Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!